Properties of High Grade Quality Polyurethane Plastics

23 March 2017

All polymers are not created equal. With this in mind, let’s delve into the properties of high-grade polyurethanes, a plastics family that consumers and industrial clients hold in high esteem. Granted, there are many polyurethane manufacturers out there, but we’re only interested in the process leaders, the PU formulations that are durable, expertly designed, and quality-assured. Performance capabilities are the indicators we’ve chosen here, so let’s see where those indicators lead our investigation.

High-Grade Durability

A hardness rating isn’t a straightforward property. In fact, a hard material can become mechanically weak if this material characteristic isn’t balanced by an intelligently added quantity of ductility. Hard products are brittle. They crack and shatter when exposed to hard knocks. Happily, a quality polyurethane product is classed initially as an elastomer. Fundamentally, a raw PU compound is rubber-like, but curing technology imbues the elastomer with a very solid material profile.

Intelligently Formulated Properties

This balanced toughness feature ranks highly on the polyurethane performance chart. The plastic just has a natural gift for delivering equal measures of hardness and impact resistance. Next, high-grade variants sidestep the issues caused by cheap fillers and substandard additives. Imagine superior property extenders, instead, chemical additives that maximise the abrasion handling abilities of an exactingly moulded part. In other words, no matter how hard the plastic part is pushed, it’ll remain like new. The product won’t wear, won’t lose its like-new lustre, and it won’t succumb to the pressures of a stress-filled application.

Geometrically Tenacious Build Quality

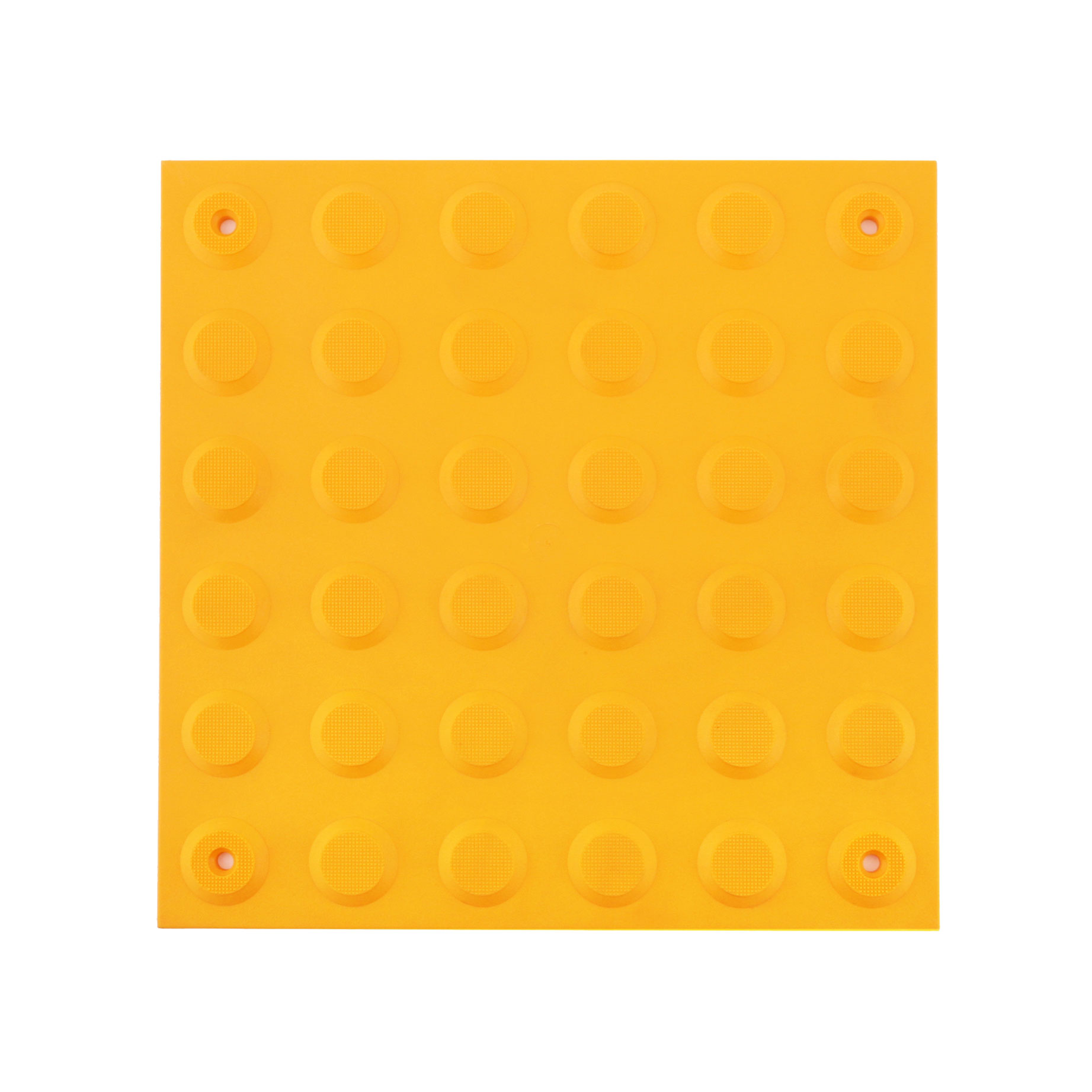

The raw material uses proprietary additives to inject the curing plastic with predetermined mechanical and material properties. Amongst these properties, elastomeric versatility boosts the moulding stage. This means the amorphous plastics base will assume the most intricate outlines, even if those outlines use thin-walled designs. The curing phase then locks the shape in place. As it assumes that final form, the detailed product architecture locks in the properties of the high-grade polyurethane base. The product is UV stable, strong but not brittle, shock resistant but not overly pliable. Last but not least, this superior plastics family handles oils and greases with casual indifference, so its material base often graces the confines of the dirtiest industrial locales.

As a high-grade plastic, a top-notch quality polyurethane base adds balanced strength to any product. Even if that merchandise is meant for a rugged industrial utilisation area, it’ll just work. Oils and caustic chemicals, jarring impact or abrasive usage, the plastic surface and its underlying plastic base will always deliver these prized properties.

Optimized by NetwizardSEO.com.au